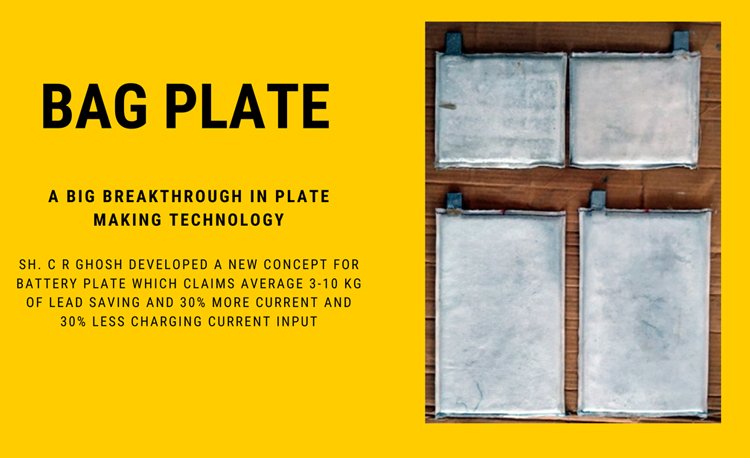

BAG PLATES- A Big Breakthrough in Plate Making Technology

An eminent name of Indian Battery Industry Sh. C R Ghosh developed a new concept for Battery Plate which claims average 3-10 Kg of Lead Saving and 30% More current and 30% less charging current input. Moreover, the manufacturer doesn’t required Spine casting machine, Pasting machine, Past mixture, Automatic Oxide filling machine to make a battery in new technology.

According to Sh. Jayant Ghosh, son of Sh. C R Ghosh ,A new pair of Positive and Negative electrodes is named as BAG PLATE, because oxide is filled in a bag with Grid. No spine is used. Both electrodes are protected from shredding. It is pasting free process of making battery plate. If you have arrangement for automotive battery system then same system will work.

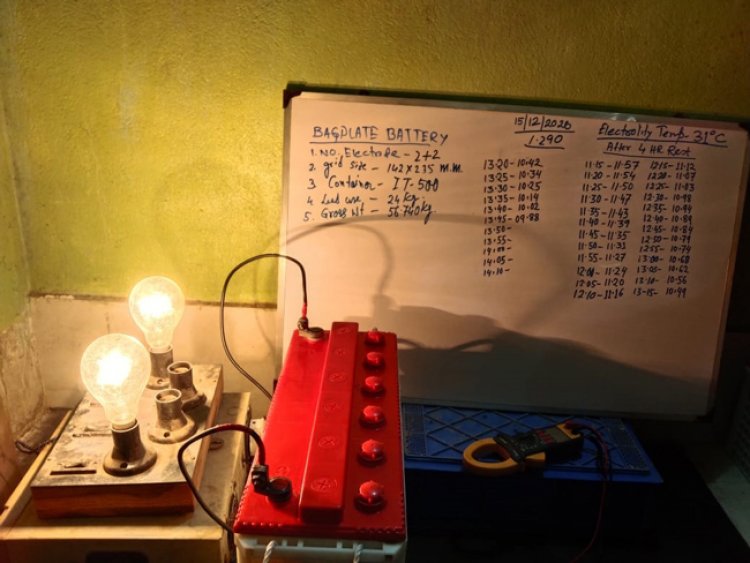

No extra machinery required other than stitching machine which will be of no significant cost. Cost of Production approximately 30% less than Tubular battery. The battery with this plate are very low internal resistance, TOC coming up to 17 volt, we have seen in inverter use no refill of D.M. water required, one can make short and tall both size plate, this has also been applied for patent to Indian and US patent office with application no 201931019694 of 17/05/2019 (India) 16699865 of 02/12/2019 (US).

Sh. Jayant further state the 30% electricity saving for both manufacturers and customers. Means 30% less Electricity Consumption in Formation and 30% less Electricity Consumption in discharge.

Gassing start at 14.8 volt compare to 13.8 volt in tubular battery, result in less DM Water TopUp.

Deep discharge up to 9V compare to 10.5V in normal tubular battery.

Another breakthrough is unique charging system, A new process of charging of plate in vat formation / Jar formation , by which we can form our plate or any plate of lead acid battery in a pollution free environment and with 50% electricity consumption.

|

|

Jayanta Ghosh is B.Tech(electrical) and had served Indian Air Force from 1992 to 2011. Since 2011 to date he become the research assistant to Mr. C.R. Ghosh and serving the Battery Industry. Sh. Jayant Ghosh can be contacted at mobile no. 97480 46012 for further clarifications.

|

|

|

Know Sh. C R Ghosh – Charter Engineer, working with lead acid battery since 1966. 1966 to 2000 with Exide – Head of technical 2001 to 2002 Abtab auto mobile Bangladesh.- technical advise 2003 Luminous – GM 2004 to 2007 Okaya auto – Director 2008 Eastman auto – Director 2009 to 2011 Deepak Power storage enterprise – Director |