Reasons of Closure order to the Amaron

The order for closedown of the factory of the Amaron battery was enormously shocking. If we look from every phase, Amar Raja is remembered as an example of The quality of battery or the safety of the workers, or the work environment. But Then what happened that the closure orders were given to Amar raja? And is it over? And what were the reasons behind the orders to close the two production units of the second-best company in the battery industry of our country?

The Crux of the matter is if the orders of closing the units were reasonable or not? Do the Units stand up to the allegations? If not, then this could be an evitable situation for those units who never were concerned about the environment they were tainting and never overseen the environmental laws they neglected or they were breaching.

Who knows when it will be the last time when those traitor units will be producing their last batch.

Let's dig into the details, why the orders were given to shut the Amaron units and, How the pollution department found deficiencies. The reasons stated in the order are as follows:

- As per the pollution department, Amaron has violated the conditions for starting production, polluted the environment, and put the health of the residents of that area in danger.

- Inside and outside the factory the level of lead found more than the prescribed level in the air and soil.

- The level of LEAD found more than the prescribed level, in the reservoir and drain near the factory.

- It was also found that the mucky water of the factory was being illegally drained into the nearby rainwater stream without being cleaned from the ETP plant.

- The water that was shed off has particles of lead that settled in the soil and polluted the soil.

- In the blood of 99.9 percent of employees, the level of LEAD found more than the prescribed limit.

- In the factory, the treated water from the atop plant was being used to irrigate the plants, which is a violation of the conditions written in the permission to start production.

- The lead blocks were kept in the open.

- The amount of lead in the common stack of oxide, grid casting, and paste making was found to be 15.2 milligrams per cubic meter.

- Extreme pollution of air was found near the water tank on the west side of the plant. The standard volume is 100ug / m3 whereas it was found 150 ug / m3.

- The acid collected in the pit was made for recycling of formation acid and the water collected on the floor after washing the factory floor was being discharged into the rainwater stream without the treatment. This polluted water reached the water tank of a nearby village and polluted it.

The entire order of shutting down the factory is published, in which the statistics of the entire operation of the pollution department and the amount of lead received from different places in the investigation are given in

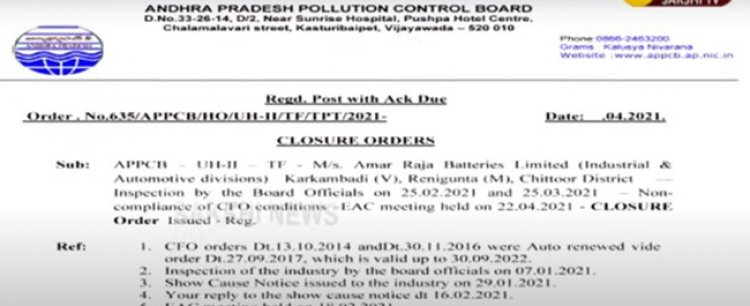

Order no. 635/APPCB/HO/UH-II/TF/TPT/2021 dt. _.04.2021

Closure Order

Sub.: APPPCB UH-II TF – M/s. Amar Raja Batteries limited. (Industrial and automotive divisions). Karkambadi (V), Renigunta (M), Chittoor district, inspection by the board officials on. 25.02.2021 and 25.03.2021. – Non-Compliance of CFO Conditions. EAC meeting held on 22.04.2021- closure order issued - Reg.

Reference.

- CFO orders. Dt 13.10.2014. and. Dt. 30.11.2016 were auto-renewed wide order dated 27.09.2017, which varied up to 30.09.2022.

- Inspection of the industry by the Board officials on 07.01.2021.

- Show cause notice issued to the industry on 29.01.2021.

- Your reply to the show cause notice dated 16.02.2021.

- EAC meeting held on 18.02.2021.

- Inspection of the industry by the Board official on 25.02.2021, 26.02.2021, 27.02.2021 and on 25.03.2021 and 26.03.2021.

- Show cause notice issued to the industry dated 06.04.2021.

- Reply to the show cause notice dated 18.04.2021 received on 20.04.2021.

- Blood level analysis report furnished by National Referral Centre for LED project in India. Bangalore.

- EAC meeting head on. 22.04.2021.

Whereas You are operating the Industry in the name M/s Amar Raja Batteries. (Industrial and automotive divisions). Karkambadi (V), Renigunta (M), Chittoor district involved in the manufacturer of batteries.

Whereas You have obtained CFO & HWA of the board vide reference. 1st Cited to manufacture industrial batteries - 2.6 M nos./ annum, Automotive batteries - 6.2 M nos./ annum, 2 Wheeler batteries 10.5 M nos./ annum

Whereas the Board randomly constituted the terms for inspection of Certain polluting industries and. Accordingly, large. No. of industries were inspected by the terms.

Whereas the board issued Show cause notice to industries observed with major noncompliances.

Whereas the board reviewed the industries in the External Advisory Committee meeting on 18.02.2021 and issued. Closure orders to some industries. Directions to some industries and recommended for re-inspection of some industries.

Whereas the board officials inspected M/s. Amara Raja Batteries, (Industrial and automotive divisions). Karkambadi (V), Renigunta (M), Chittoor district on 07.01.2021 and observed certain non-compliances.

Whereas the board issued a show-cause notice to the industry date 29.01.2021.

Whereas you have submitted a reply to the show cause Notice date 16.02.2021.

Whereas vide reference 5th Cited. you are given an opportunity before the External Advisory Committee. 18.02.2021 and the committee recommended for re-inspection by the special terms to. Evaluate the non-compliance of CEO condition.

Whereas vide ref. 6th cited. The special terms constituted by the board, inspected the industry and. Observed the following:

- The Value of Lead in the common stack attached to oxide and grid casters & Paste preparation Section (LVRLA Plant) is 15.2 mg/NM3 and Particulate matter is 38.7mf/NM3 against the standard of 10 mg/NM3 and 25 mg/NM3 respectively (monitored on 27.02.2021).

- The value of PM 10 in the Ambient Air as per the Ambient Air quality monitoring conducted near a water tank in the west direction of the plant is 150 ug/m3 against the standard of 100ug/m3 (monitored on 27.02.2021)

- The value of lead in the treated wastewater from the outlet of the ETP at the SBD unit is 0.119 mg/I against the standard of 0.1 mg/I.

- The sample of water Collected from the WRS Formation drain near the LVRLA office is 0.128 mg/I against the standard of 0.1 mg/I. (collected on 25.02.2021)

- The water sample collected from the pond outside the industry premises has lead 0.0226 mg/I against the acceptable standard of 0.01mg/l (drinking water standard). The sample has a COD of 192 Mg/I.

- The Water sample Collected from the lake in the northeast direction of the plant has lead 0.0889 mg/I against the acceptable standard of 0.01mg/l (drinking water standard). The sample has COD 104 mg/I.

- As per the analysis reports of the samples collected, the concentration of the lead in the untreated sewage illegally discharging into stormwater drains is 2.10 mg/lit and in the partially treated sewage, the concentration of the lead is 0.346 mg/lit (prescribed discharge standard for lead concentration in the treated wastewater is 0.1 mg/lit). The lead levels in the STP sludge is also indicating contamination of domestic wastewater with the lead presence in raw sewage and treated domestic wastewater.

- It was observed from the monitoring reports that the blood lead in 99.9% of employees (3533 nos) is exceeding the acceptable level of 10 mcg/dl.

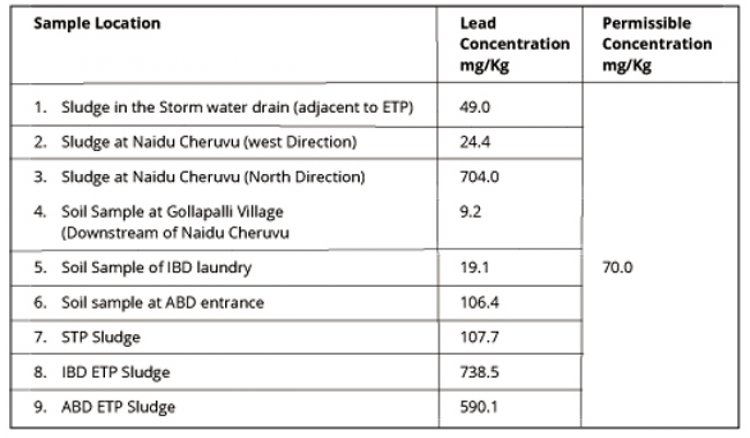

- During the Inspection, samples were collected from the stormwater drain, sludge samples from Naidu Cheruvu at two locations and at Gollapalli village (downstream of Naidu cheruvu)

From the above, It was inferred that the higher concentration of the lead levels in the soil sample is clearly indicating that the lead accumulation in the soil occurred due to the application of treated wastewater having lead traces, spillages and also caused stratification of the heavy metals in the soil, thereby causing contamination runoff and also draining the lead into surface water tank existing in the downstream of the industry. (As per the MoEF document, i.e. guidelines document for the assessment and remediation of contaminated site in India, March 2015, the permissible concentration of lead is 70 mg/kg. for agriculture use)

- As per the analysis report of the sludge samples collected from Naidu Charuvu existing at the downstream of the industry, which is also the immediate recipient of the stormwater runoff, treated or untreated industrial effluents/ Savage indicating the lead level of 24.4. mg/kg and 704mg/kg respectively, indicating contamination of the water body with lead.

- In view of the ambiguous pattern of flow meters maintained by the industry for water consumption/ wastewater generation, verifiable data is not available with the industry to assess the water consumption/wastewater generation.

- The industry has not maintained a quantitative flow sheet of water balance for three production divisions. When compared with the quantities mentioned in the CFO order, The water consumption and wastewater quantities were not at all matching at the side table, As per details furnished by the industry during the inspection.

- The industry has not provided a clarifier for the AB division, thus the ATP for AB division is not a full-fledged one.

- The industry is utilizing treated trade affiliates for gardening instead of reuse in the process, violating CFO conditions.

- The stormwater drains are connected to Karakambadi Tank to discharge stormwater during the rainy season. Whereas the stormwater drain was found with traces of effluents during non-rainy seasons, So there is every possibility of bypassing the effluents Into the Karakambadi tank.

- The industry has not provided a covered shed for storing the lead ingots.

- The industry is not meeting the prescribed discharge standard. As per the analysis reports of the treated sewage sample collected on 26th March 2021, the value of BOD is 40 mg/l against the standard of 20 mg/lt.

- The industry has disconnected the pump at the formation acid recycling pit (ABD) and is not treating / Recycling the effluent. It was observed that pipes conveying the floor washings, Process Condensate, and Other wastewater at several locations is directly connected to stormwater drain and large quantities of wastewater flow observed in the stormwater drain at the time of the inspection, which is being discharged outside the premises and joining into the water tank in downstream (locally called Naidu Cheruvu). As per the analysis report of the samples collected, the lead level is 0.083 mg /LIT and 0.063 Mg /Lit In the drain, adjacent to ETP and waste samples of Naidu Cheruvu.

- It was observed that the industry is utilizing the treated wastewater from the individual units for Green belt development / Avenue plantation along with treated sewage and RO rejects. As per the analysis report of the soil samples, inlet, and outlet of STP, STP Sludges the lead level in these samples, indicating that the treated wastewater and applications of the treated effluent for green belt development resulting in the accumulation of lead concentration in the soil. Further, the accumulated pollutants are the potential to cause contamination of the runoff, thereby resulting in soil contamination and runoff path.

- The board is stipulated as a condition in the CFO order dated. 30.11.2016 to construct and Commission the additional ETP of 100 CLD capacity before September. 2017. But the industry has not constructed and commissioned the additional ATP, not complied with CFO conditions. The ATP sludge is packed in PP woven sack bags and stored Openly. A closed shed was not provided for storage of the same.

- The industry has provided STP of 500 M3 capacity to cater to domestic wastewater generated from the industry and nearby townships. During the inspection on 25.3.2021, It was observed that the industry has laid 2 numbers of underground pipelines from STP to stormwater drain, leading to a water tank. The industry is indulging in the illegal discharge of untreated domestic wastewater, bypassing the treatment in STP through one pipeline, and through another pipeline they were discharging partially treated domestic wastewater from the STP in a stormwater drain, thereby violating the CFO issue by the board.

- Whereas the board officials collected the blood samples for the presence of led and tested by National Referral Centre for Lead (pb) projects in India (NRCLPI) End found the values to be far in excess of the standard. (10 ug/dl.) The blood lead value has exceeded in villagers by 30%. The excess lead values in blood samples of the surrounding villagers show. That the operation of your unit is endangering public health.

Whereas from the above observations of the board officials. It was observed that you are. Polluting the ambient. air. Lead in the common stack, measured on. 27.02.2021 is. 15.2 mg/NM3 Against the standard of 10 mg/NM3. Discharging the untreated wastewater into drains, polluting the water. Sample of the. Water collected from the WRS formation drain near the LVRLA office is. 0.128 mg/I against. The standard of 0.1 mg/l, untreated sewage illegally. discharging into the stormwater drain is. 2.10mg/lit. causing soil. Pollution lead value 704 mg/kg against the MOEF. Stipulated screening value of Lead. concentration in soil 70 mg/kg for agriculture.

Whereas the presence of lead in the human body will cause severe damage to various organs of the human body which is observed by the multi. Disciplinary committee report. On the recent public health issue in Eluru.

Where is. From the above, it is observed that you are caring for the operations, violating the CFO conditions. And polluting the environment and end endangering public health.

Whereas the board issued a Show-cause notice to the industry date 06.04.2021 mentioning the above noncompliances.

Whereas you have submitted a reply to the Show cause Notice date 18.04.2021 received on 20.04.2021.

Whereas you are called for the legal hearing on 22.04.2021, before the External Advisory Committee and given on opportunity. For hearing before the committee. The committee observed. That the industry is violating. Several conditions of the board.

Where is the principle of natural justice? The industry was given. Several opportunities.

After a detailed discussion, the committee recommended the issue of the Closure Order. The board Hereby issues a Closure order to M/s Amara Raja batteries. (Industrial and automotive divisions). Karkambadi (V), Renigunta (M), Chittoor district for noncompliance of the CFO. Conditions under section 33. (A) of water (Prevention and control of pollution) Amendment Act. 1988 and under section 31 (A) of air (prevention and control of Pollution) Amendment Act. 1987 and under Hazardous Waste (management and transboundary movements) rules, 2016.

M/s A.P.S.P.D.C.L. has been Requested to disconnect the power supply to M/s. Amara Raja Batteries. (Industrial and Automotive divisions) Karkambadi (V) Renigunta (M) Chittoor district.

You are further directed. To take note that if you continue to operate your unit after receipt of this order, you will be liable for prosecution U/s 41 of water (prevention and control of pollution) Act 1974 and amendments. Thereof and U/s 37 (l) Of air (prevention and control of Pollution) Act 1981 and amendments. Thereof, the punishment under this section. Will be imprisonment for a Term Which shall not be less than one year six months but which may extend to six years and with fine.

You are also directed to take note that the. Ms. A.P.S.P.D.C..L., Has been ordered to disconnect. Electricity supply to your unit with immediate effect. Should you resort to operate your unit by means of a diesel generator or any machine mechanical device you will be attracting Prosecution U/s 41 of water (prevention and control of pollution) Act 1974 and amendments. Thereof and U/s 37 (l) of air (prevention and control of Pollution) Act 1981 and amendments thereof.

This order comes into effect from today. i.e. 04.2021

Member secretary.

To.,

M/s. Amara Raja batteries limited (Industrial and automotive divisions)

Karkambadi (V),

Renigunta (M),

Chittoor District

Copy to:

The joint Chief, Environmental engineers. Zonal office, Kurnool for information and necessary action.

The Environmental Engineer, Regional office, Tirupati, Chittoor District for information and necessary action - it is directed to submit compliance report within 24 hours.

Read this Article in Hindi Language: https://thebatterynews.com/why-closure-order-to-Amaron